IronRidge offers two “full stack” flush mount systems for pitched roof applications: the Aire System and XR System.

Each includes clamps, rails, and an array of attachments that will enable installers to securely mount arrays on composition shingle, tile, slate, and shaker shingle roofs.

Our components have been tested to the limit and proven in extreme environments, including Florida’s high-velocity hurricane zones.

This rigorous approach has led to unique structural features, such as curved rails and reinforced flashings, and is also why our products are fully certified, code compliant and backed by a 25-year warranty.

We respect the roof.

Pitched Roof System Components

| Image | Name | Description | Product Type | Product Line |

|---|---|---|---|---|

|

QuickMount® HUG™ – Halo UltraGrip™ | QuickMount® HUG® The Respect Your Roof Deserves Due to recent innovations, many asphalt shingles now have bonded courses. A mount that protects without prying shingles can really speed things up.... | Attachment | QuickMount® |

|

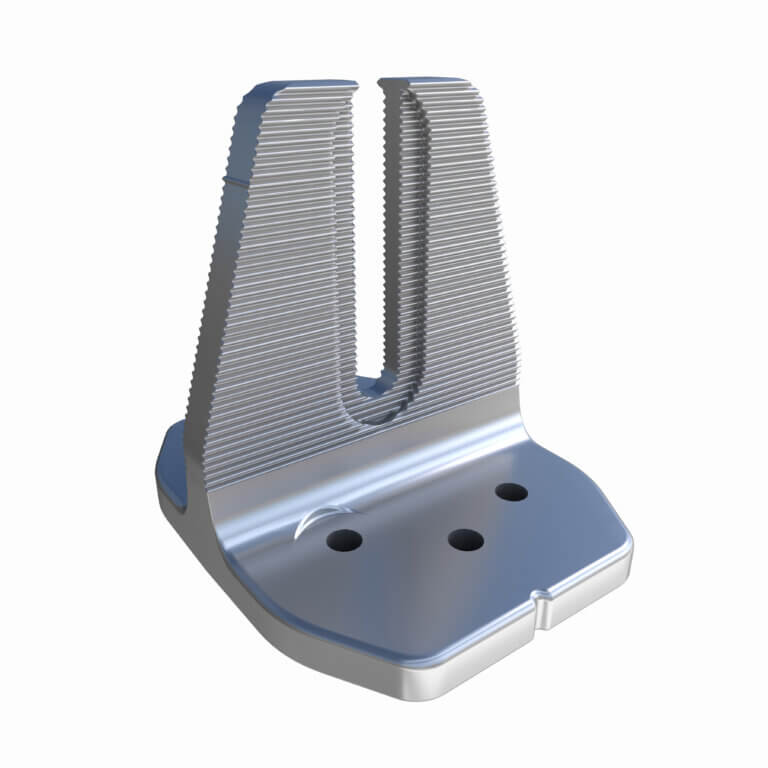

XR Rail® Family | XR Rails® have a unique curved profile that increases structural strength and spanning capability, meaning fewer roof penetrations and more cost-effective designs. | Racking | IronRidge |

|

BOSS® Bonded Structural Splice | The BOSS® provides a strong, bonded connection for XR Rails®. No assembly, tools, or hardware required. | Racking | IronRidge |

|

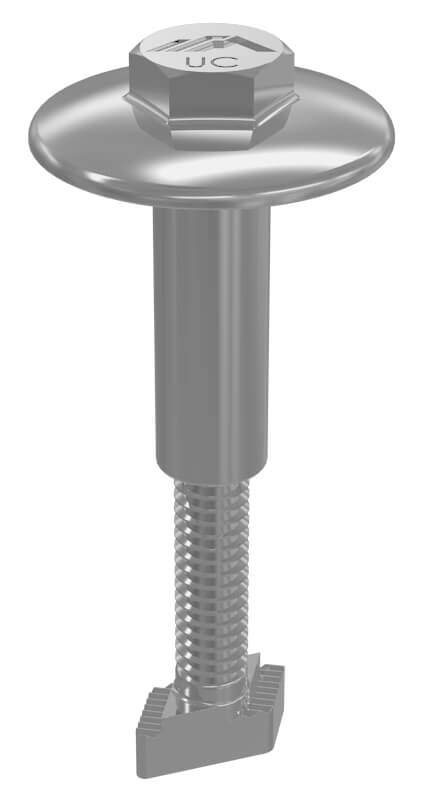

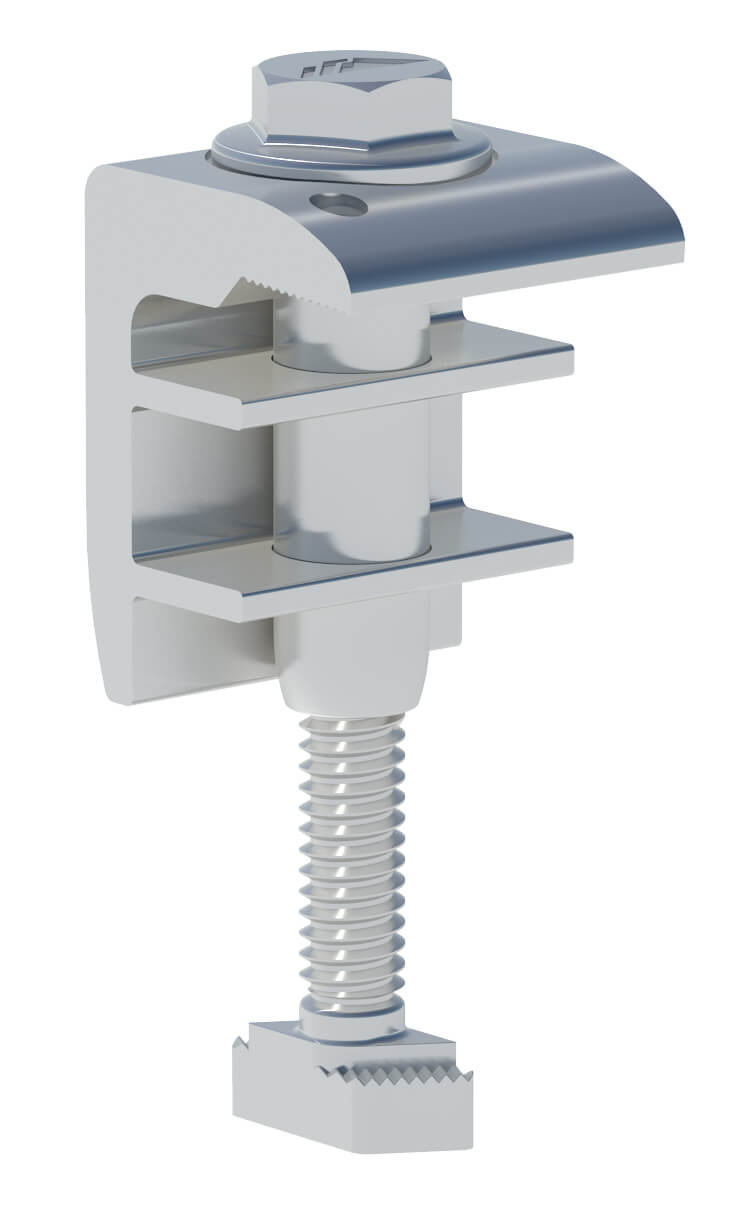

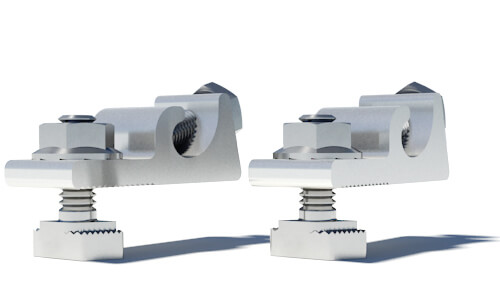

UFO® | The Universal Fastening Object is a universal, single-piece mid clamp. When combined with a Stopper Sleeve, the UFO® functions as an end clamp. | Hardware | IronRidge |

|

EFO — Universal End Clamp | EFO™ — End Fastening Object Universal End Clamps for XR Rails The IronRidge EFO™ is here. We redesigned the end-clamp system for XR Rails®, which originally used Stopper Sleeves to... | Hardware | IronRidge |

|

Eclipse | XR Hidden End Clamp | Eclipse — XR Hidden End Clamp Keeping Solar Clean & SleekMost solar installations use mounting rails and fasteners to secure modules to the building structure, but these clamping components can... | Hardware | IronRidge |

|

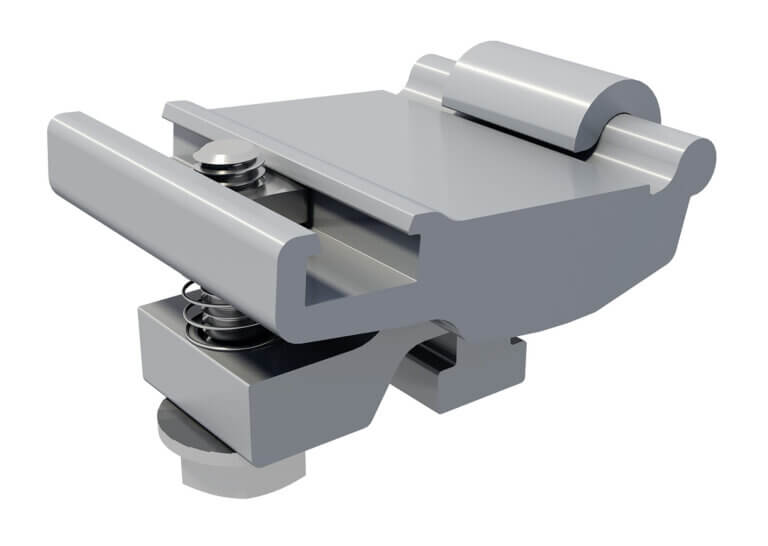

CAMO™ | This tool-free, universal, invisible end clamp is designed to bond and secure while improving array aesthetics. It comes as one piece, fully assembled. | Hardware | IronRidge |

|

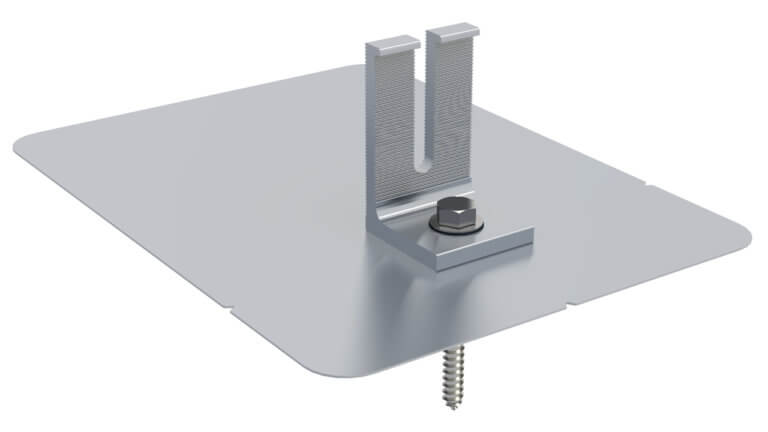

FlashVue® | Optimized flashing design features a large viewport, for easy alignment with the pilot hole. The GripCap also stays snug in place. | Attachment | IronRidge |

|

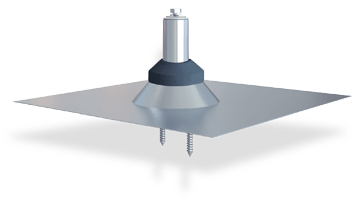

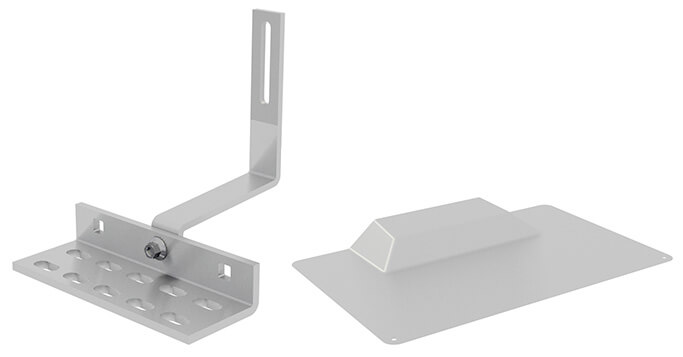

FlashFoot2® | Flash and mount XR Rails® on asphalt comp shingle roofs with superior waterproofing. The twist-on cap eases installation. | Attachment | IronRidge |

|

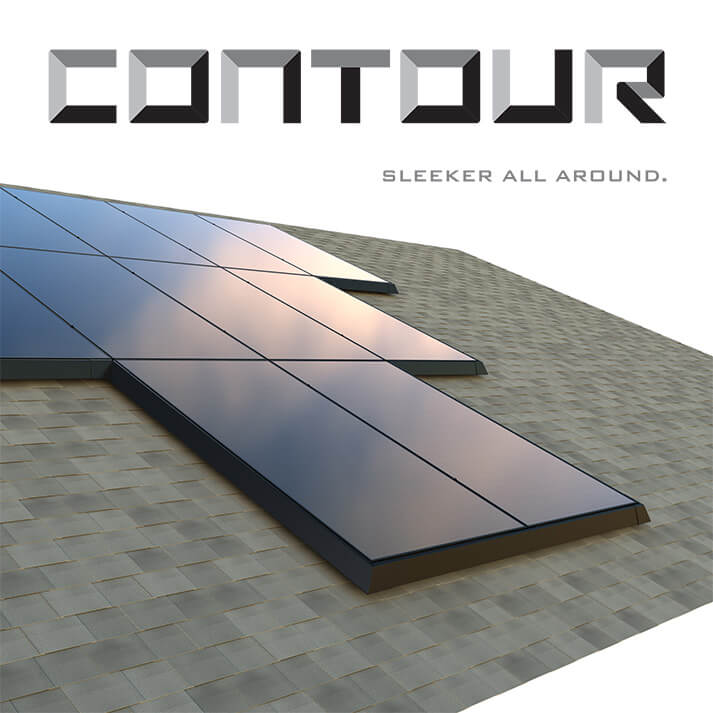

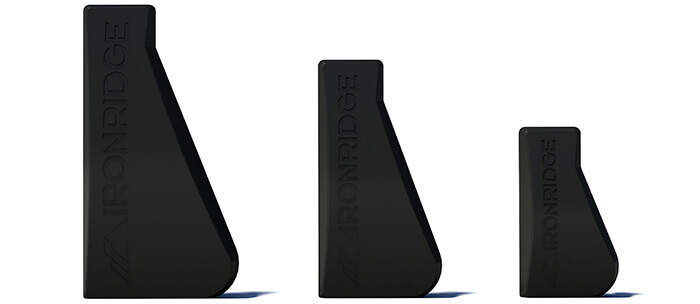

Contour™ Trim – Solar Array Skirt | Contour® Solar Array Trim Aesthetic Arrays, Sleeker All Around IronRidge Contour® Trim elevates the look of any solar array by providing a sleek trim (or skirt) across the south edge... | Accessory | IronRidge |

|

Flat Tile Fly | Flat Tile Roof Attachment | Flat Tile Fly Make Flat Tile Projects Fly!The Flat Tile Fly joins our fleet of tile roof attachment options—offering a cost-effective, flat-tile-hook solution with an open-slot for installation ease.It comes... | Attachment | IronRidge |

|

QuickMount® Tile Conduit Mount | QuickMount® Tile Conduit Mount Easily Mount Conduit on Tile Roofs The QuickMount® Tile Conduit Mount is a newly designed attachment for mounting conduit on tile-roof solar projects. It has a small profile for easy handling and flexible installations.... | Attachment | QuickMount® |

|

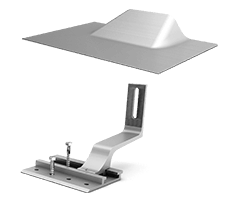

Comp Shingle Flashing, US | Comp Shingle Flashing, US The Comp Shingle Flashing (US-made) is a versatile solution for attaching solar to composition shingle roofs. The flashing installs quick and easy with a single fastener.... | Attachment | IronRidge |

|

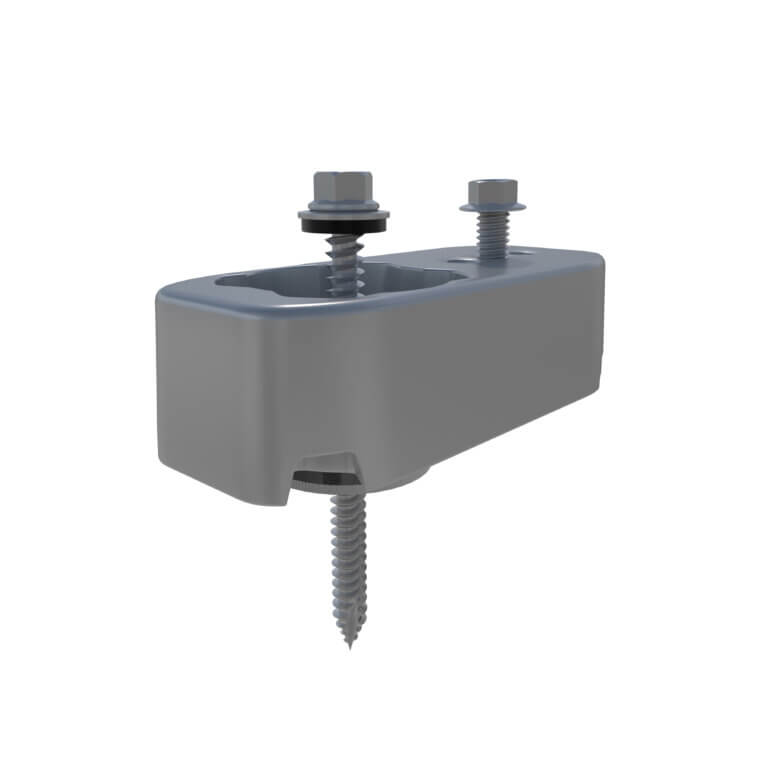

QuickMount® BUG™ – Conduit Mount | QuickMount® BUG™ Keep Your Conduit Snug The QuickMount® BUG™ is our latest conduit mount. Compact, sturdy and unobtrusive—leveraging the same proprietary UltraGrip™ flashing system as the HUG™ attachment. BUG™ comes... | Accessory | QuickMount® |

|

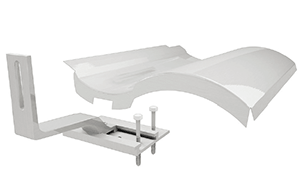

L-Mount® | The L-Mount® is designed for cost-effective, one-bolt installation onto existing composition/asphalt shingle roofs. | Attachment | QuickMount® |

|

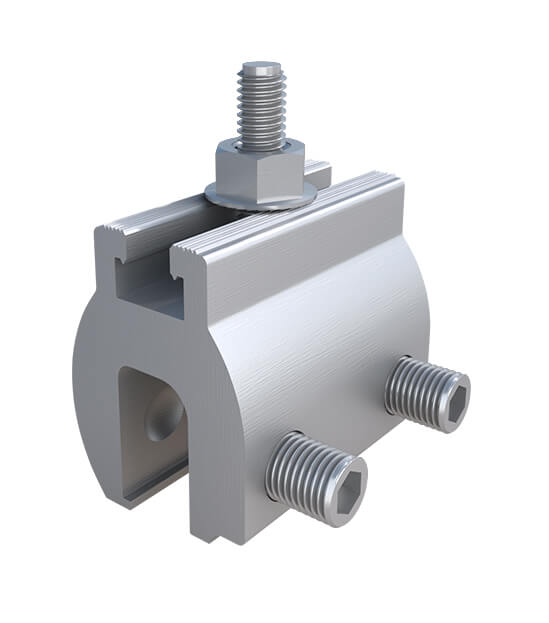

Lynx™ Metal Roof Attachment | The QuickMount® Lynx™ is a robust, non-penetrating clamp for attaching solar to standing seam metal roofs. Connect with confidence. | Attachment | QuickMount® |

|

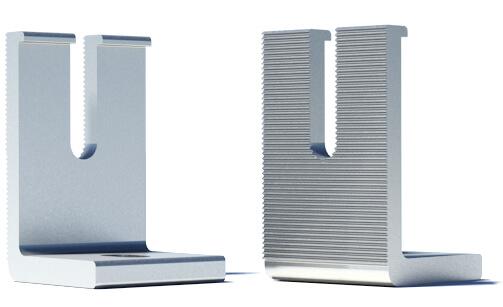

IronRidge® Slotted L-Foot | Our original Slotted L-Feet are engineered for most roof mounting applications. Vertical slots allow for easily dropping in rails. | Attachment | IronRidge |

|

JayBox® Junction Box | JayBox® Junction Box Protect the Nest JayBox® is an ever-adaptable junction box, designed to securely enclose wires on nearly any solar project—with ample space to shelter up to 4 module strings.... | Accessory | QuickMount® |

|

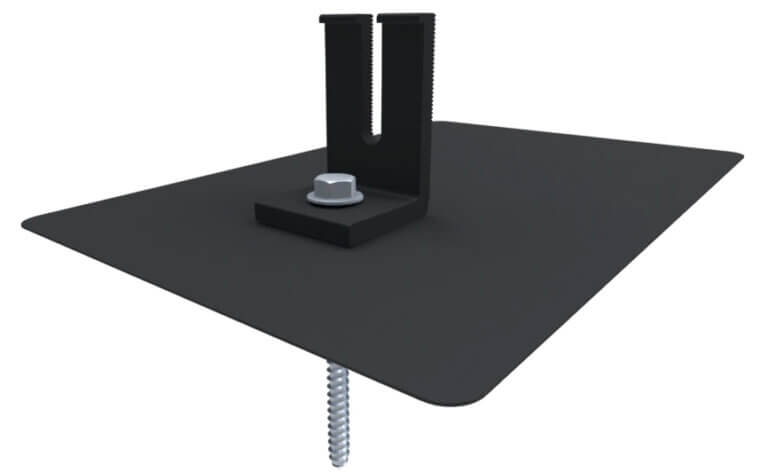

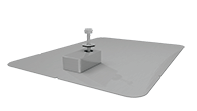

QBase® Composition Mount | The QBase® Composition Mount is a strong and cost-effective method for installing solar panels during the construction of new composition/asphalt shingle roof for either a new home or a roof replacement. | Attachment | QuickMount® |

|

QBase® Metal, Shake & Slate Mount | The QBase® Metal, Shake & Slate Mount is a multi-purpose base-and-post style solar mounting system offering superior strength and waterproofing for metal shingle, shake, and slate shingle roofs. | Attachment | QuickMount® |

|

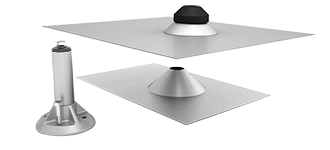

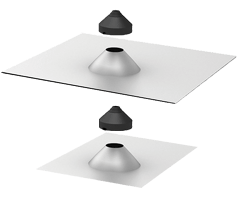

QBase Universal Tile Mount | The QBase Universal Tile Mount uses the QBase foundation and two spun aluminum cone flashings for installing solar panels on tile roofs with superior strength and waterproofing. | Attachment | QuickMount® |

|

Tile Replacement Mount | The Tile Replacement Mount provides a fast and easy way to install solar on tile roofs while protecting against water intrusion. | Attachment | QuickMount® |

|

Tile Replacement Flashings | The QuickMountTile Replacement Flashing replaces a tile, so there’s no messy, time-consuming tile grinding or cutting required. Works with all standard curved and flat tile roofs, and all standard rail-based racking systems. | Attachment | QuickMount® |

|

Classic Conduit Mount | The Classic Conduit Mount lifts electrical conduit off the roof to protect wiring from overheating. These mounts use our proprietary waterproofing technology to seal the roof penetrations. | Attachment | QuickMount® |

|

Conduit Penetration Flashing | Provides a quick, easy way to install a variety of conduit sizes through composition shingle roofs while protecting the penetration against water intrusion. | Attachment | QuickMount® |

|

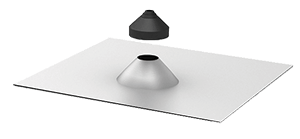

Tile Conduit Penetration Flashing | The QuickMount® Tile Conduit Penetration Flashing provides a quick, easy way to install conduit through tile roofs while protecting against water intrusion with two seamless, all-aluminum spun cone flashings. | Attachment | QuickMount® |

|

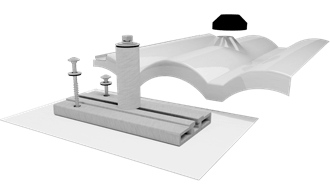

Quick Hook® for Side Mount Rails | Quick Hook® is fast and simple to install. Two height options allow for use with a variety of flat and curved tiles for mounting PV on tile. | Attachment | QuickMount® |

|

Accessory Frame Bracket | The Accessory Frame Bracket offers fast, on the ground installation for mounting module level electronics directly to the module frame. It works with rail-based racking systems, ballasted, and ground-mounted systems. | Accessory | QuickMount® |

|

Conduit Mount | Elevates and securely fastens conduit to the roof deck. Supports ¾” or 1” EMT conduit and other equipment such as a junction box for a sleek, versatile solution. | Attachment | IronRidge |

|

Knockout Tile | The single-lag design cuts the number of tile roof penetrations in half, and the fully-encased compression seal keeps the water down and out. | Attachment | IronRidge |

|

All Tile Hook & Deck Flashing | The single-lag design cuts the number of tile roof penetrations in half, and the fully-encased compression seal keeps the water down and out. | Attachment | IronRidge |

|

Accessories | Provide a finished look and support electrical wires. Constructed from UV-stabilized polymers for long-lasting performance: End Caps & Wire Clips. | Accessory | IronRidge |

|

Hardware | All hardware is designed for single-tool installs, low profiles, and in support of our UL 2703 listings: Grounding Lugs, T-bolts, Square-bolts and MI kits. | Hardware | IronRidge |