All-Terrain Mounting

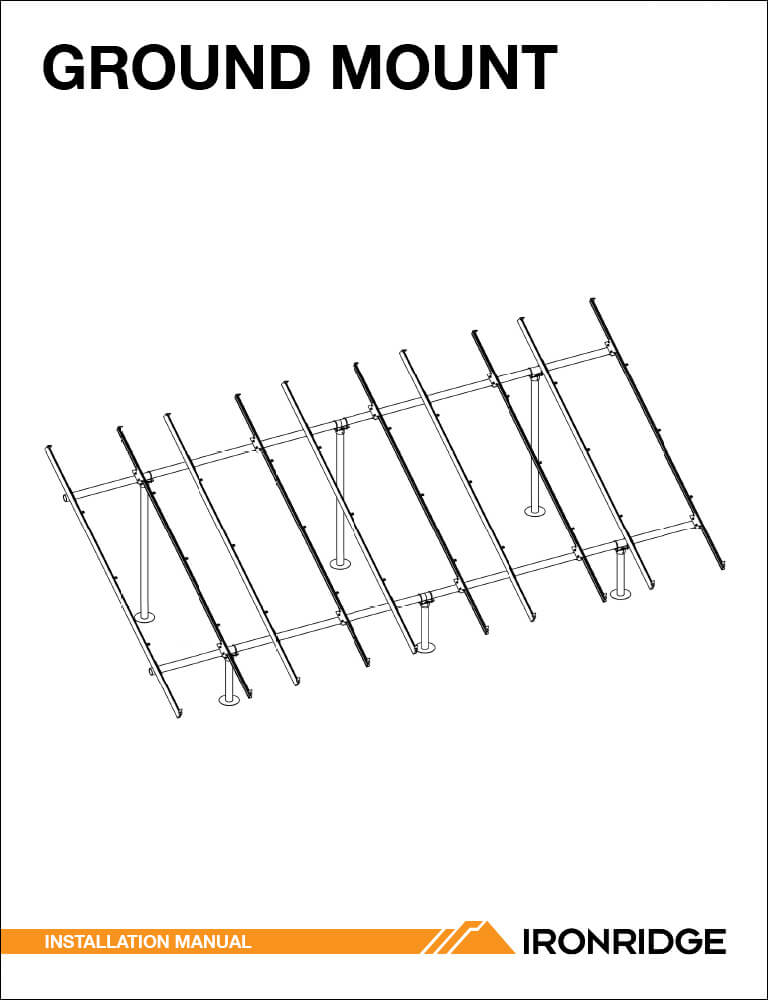

The IronRidge® Ground Mount System combines our XR100® or XR1000® Rails with locally-sourced steel pipes or mechanical tubing, to create a cost-effective structure capable of handling any site or terrain challenge.

Installation is simple with only a few structural components and no drilling, welding, or heavy machinery required. In addition, the system works with a variety of foundation options, including concrete piers and ground screws. Compatible with soil classes 2-4.

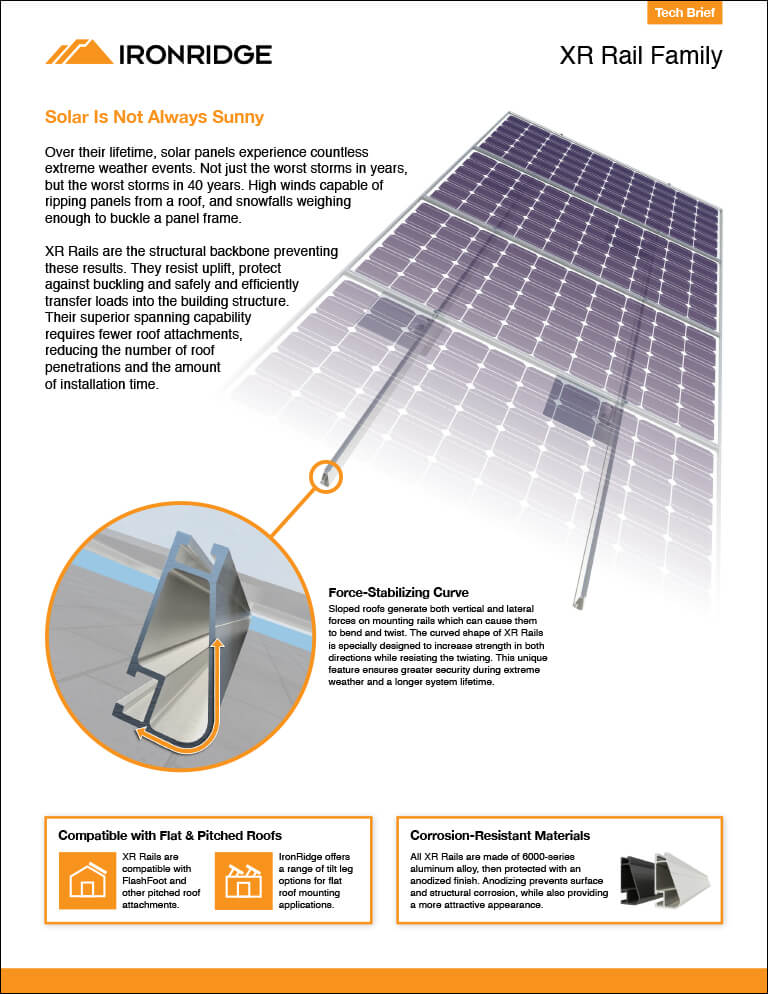

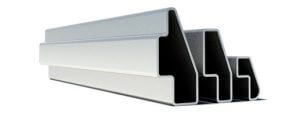

XR Rails

XR Rails are the backbone of the solar array. Their unique curved profile increases structural strength and spanning capability, allowing for fewer roof penetrations and more cost-effective system designs.

XR Rail are available in three targeted sizes: XR10, XR100 & XR1000. Each size supports specific design loads, while minimizing material costs. Depending on your location, there is an XR Rail to match.

All XR Rails are made of marine-grade aluminum alloy, then protected with an anodized finish. Anodizing protects against surface and structural corrosion, while also providing a more attractive appearance.

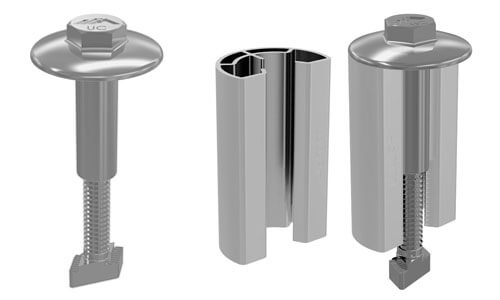

UFOs (Universal Fastening Objects)

UFOs are one-size-fits-all, single-piece fasteners that quickly and securely bonds solar modules to XR Rails. They come lubricated and assembled, with a sleek, low-profile design. Simply snapping on a Stopper Sleeve transforms the UFO into an end clamp.

UFOs are one-size-fits-all, single-piece fasteners that quickly and securely bonds solar modules to XR Rails. They come lubricated and assembled, with a sleek, low-profile design. Simply snapping on a Stopper Sleeve transforms the UFO into an end clamp.UFOs are made of stainless steel and available in clear or black finishes.

FlashFoot2

The FlashFoot2 is an all-in-one roof attachment for mounting XR Rails to composition shingle roofs. Its integrated design incorporates both structural and waterproofing features into a single assembly.

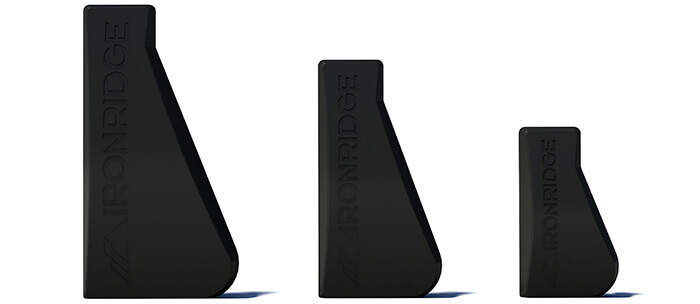

Stopper Sleeve

The Stopper Sleeve snaps onto the IronRidge UFO to transform it into an end clamp.

It comes in clear and black finishes and 6 different sizes to accommodate a range of module frames.

Tilt Legs

Tilt Legs are available in multiple lengths to support a wide range of mounting angles. The Fixed Tilt Leg Kit includes a North & South Tilt Leg, plus hardware for attaching to XR Rails.

South Tilt Legs come assembled and feature angle indicator markings to simplify installation. North Tilt Legs consists of a slotted aluminum tube and a pivot bracket for full adjustability.

XR Rail Assembly

Modules are clamped to XR1000 rails to create a column between the North (high) and South (low) cross pipes. XR1000 rails support up to 5 modules per column in landscape orientation.

Modules are clamped to XR1000 rails to create a column between the North (high) and South (low) cross pipes. XR1000 rails support up to 5 modules per column in landscape orientation.All components for the rail assembly are available in clear or black finishes, and clamps are available in a range of sizes to match all common module frames.

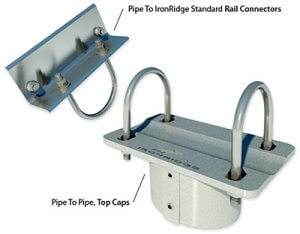

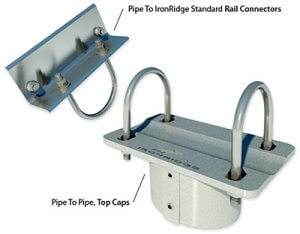

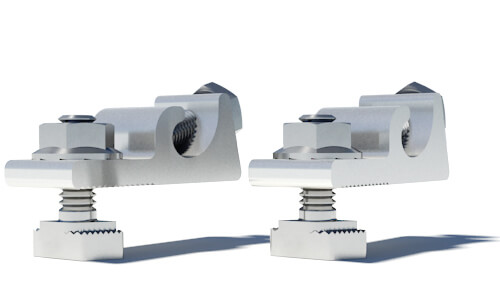

Top Cap & Rail Connector

Cast aluminum Top Caps quickly attach to vertical posts with set screws, and also support cross pipes using companion U-bolt hardware.

Top Caps are available for 2” and 3” schedule-40 pipe and mechanical tubing.

Rail Connector attach XR1000 Rails to the cross pipes using 3/8” nuts and bolts.

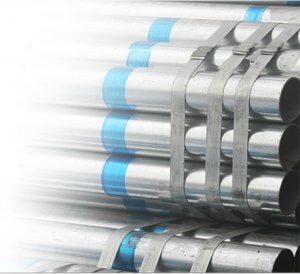

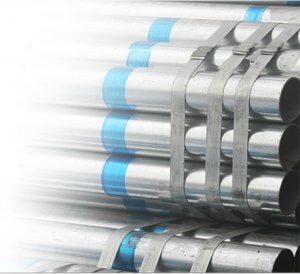

Pipe & Mechanical Tubing

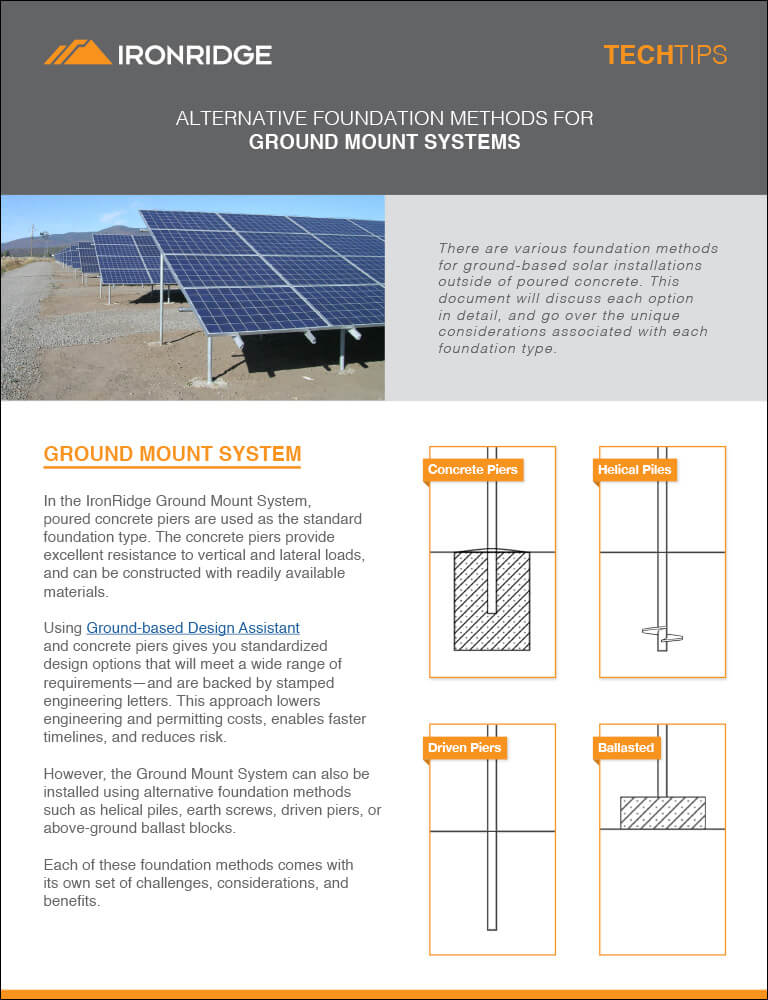

The Ground Mount System uses either schedule-40 steel pipe or mechanical tubing (e.g. Allied Flo-Coat, Gatorshield, Gatorshield Plus) as the primary structural element.

Locally-sourced steel pipe and mechanical tubing minimizes materials and shipping costs, while increasing the speed and flexibility of construction.

In addition, the Ground Mount System works with concrete piers, pile-driven piers, and many other foundation types.

Diagonal Braces

Diagonal Braces are optionally available for severe load conditions to provide extra stability in the North-South direction.

Diagonal Braces are optionally available for severe load conditions to provide extra stability in the North-South direction.The Diagonal Brace is shipped with all hardware needed for installation between the north and south posts.

XR Rails

XR Rails are the backbone of the solar array. Their unique curved profile increases structural strength and spanning capability, allowing for fewer roof penetrations and more cost-effective system designs.

XR Rail are available in three targeted sizes: XR10, XR100 & XR1000. Each size supports specific design loads, while minimizing material costs. Depending on your location, there is an XR Rail to match.

All XR Rails are made of marine-grade aluminum alloy, then protected with an anodized finish. Anodizing protects against surface and structural corrosion, while also providing a more attractive appearance.

UFOs (Universal Fastening Objects)

UFOs are one-size-fits-all, single-piece fasteners that quickly and securely bonds solar modules to XR Rails. They come lubricated and assembled, with a sleek, low-profile design. Simply snapping on a Stopper Sleeve transforms the UFO into an end clamp.

UFOs are one-size-fits-all, single-piece fasteners that quickly and securely bonds solar modules to XR Rails. They come lubricated and assembled, with a sleek, low-profile design. Simply snapping on a Stopper Sleeve transforms the UFO into an end clamp.UFOs are made of stainless steel and available in clear or black finishes.

FlashFoot2

The FlashFoot2 is an all-in-one roof attachment for mounting XR Rails to composition shingle roofs. Its integrated design incorporates both structural and waterproofing features into a single assembly.

Stopper Sleeve

The Stopper Sleeve snaps onto the IronRidge UFO to transform it into an end clamp.

It comes in clear and black finishes and 6 different sizes to accommodate a range of module frames.

Tilt Legs

Tilt Legs are available in multiple lengths to support a wide range of mounting angles. The Fixed Tilt Leg Kit includes a North & South Tilt Leg, plus hardware for attaching to XR Rails.

South Tilt Legs come assembled and feature angle indicator markings to simplify installation. North Tilt Legs consists of a slotted aluminum tube and a pivot bracket for full adjustability.

XR Rail Assembly

Modules are clamped to XR1000 rails to create a column between the North (high) and South (low) cross pipes. XR1000 rails support up to 5 modules per column in landscape orientation.

Modules are clamped to XR1000 rails to create a column between the North (high) and South (low) cross pipes. XR1000 rails support up to 5 modules per column in landscape orientation.All components for the rail assembly are available in clear or black finishes, and clamps are available in a range of sizes to match all common module frames.

Top Cap & Rail Connector

Cast aluminum Top Caps quickly attach to vertical posts with set screws, and also support cross pipes using companion U-bolt hardware.

Top Caps are available for 2” and 3” schedule-40 pipe and mechanical tubing.

Rail Connector attach XR1000 Rails to the cross pipes using 3/8” nuts and bolts.

Pipe & Mechanical Tubing

The Ground Mount System uses either schedule-40 steel pipe or mechanical tubing (e.g. Allied Flo-Coat, Gatorshield, Gatorshield Plus) as the primary structural element.

Locally-sourced steel pipe and mechanical tubing minimizes materials and shipping costs, while increasing the speed and flexibility of construction.

In addition, the Ground Mount System works with concrete piers, pile-driven piers, and many other foundation types.

Diagonal Braces

Diagonal Braces are optionally available for severe load conditions to provide extra stability in the North-South direction.

Diagonal Braces are optionally available for severe load conditions to provide extra stability in the North-South direction.The Diagonal Brace is shipped with all hardware needed for installation between the north and south posts.

Rugged Construction

Engineered steel and aluminum components ensure durability

UL 2703 Listed System

Entire system and components meet newest effective UL 2703 standard.

PE Certified

Pre-stamped engineering letters available in most states.

Flexible Architecture

Multiple foundation and array configuration options.

25-Year Warranty

Products guaranteed to be free of impairing defects.

Design Assistant

Online software makes it simple to create, share, and price projects.

Components

| Image | Name | Description | Product Type | Product Line |

|---|---|---|---|---|

|

XR Rail® Family | XR Rails® have a unique curved profile that increases structural strength and spanning capability, meaning fewer roof penetrations and more cost-effective designs. | Racking | IronRidge |

|

BOSS® Bonded Structural Splice | The BOSS® provides a strong, bonded connection for XR Rails®. No assembly, tools, or hardware required. | Racking | IronRidge |

|

UFO® & Stopper Sleeves | The Universal Fastening Object is a universal, single-piece mid clamp. When combined with a Stopper Sleeve, the UFO® functions as an end clamp. | Hardware | IronRidge |

|

CAMO™ | This tool-free, universal, invisible end clamp is designed to bond and secure while improving array aesthetics. It comes as one piece, fully assembled. | Hardware | IronRidge |

|

JayBox® Junction Box | JayBox® Junction Box Protect the Nest JayBox® is an ever-adaptable junction box, designed to securely enclose wires on nearly any solar project—with ample space to shelter up to 4 module strings.... | Accessory | QuickMount® |

|

Diagonal Cross Brace | Optional assembly kit is for those rare installations that require extra support. Includes the brace, sleeves, and hardware. | Racking | IronRidge |

|

Rail Connector | Attaches and bonds horizontal cross pipes to XR1000 Rails. Available for both 2” and 3” sizes. | Racking | IronRidge |

|

Top Cap | Available in sizes that fit either 2” or 3” steel pipe and mechanical tubing, the top cap supports cross pipes with U-bolt hardware. | Racking | IronRidge |

|

Accessories | Provide a finished look and support electrical wires. Constructed from UV-stabilized polymers for long-lasting performance: End Caps & Wire Clips. | Accessory | IronRidge |

|

Hardware | All hardware is designed for single-tool installs, low profiles, and in support of our UL 2703 listings: Grounding Lugs, T-bolts, Square-bolts and MI kits. | Hardware | IronRidge |

Pipe and Tubing

Locally-sourced 2” or 3” schedule 40 pipe and mechanical tubing help you save on freight, while still spanning up to 18’ between vertical piers.

Schedule 40 Pipe

- 3” pipe: OD 3.5”, wall thickness 0.216”, 35ksi yield strength

- 2” pipe: OD 2.38”, wall thickness 0.154”, 35ksi yield strength

Mechanical Tubing

- 3” Tubing: OD 3.5”, wall thickness 0.165”, 45ksi yield strength

- 2” Tubing: OD 2.375”, wall thickness 0.109”, 50ksi yield strength

Hex-Head Set Screws

This custom component is required to connect the IronRidge Ground Mount foundation pipe to the ground screw. These hex-head set-screws provide corrosion protection and a thread-locking coating to ensure fasteners don’t loosen over time. IronRidge has designed and tested this set-screw for use with American Ground Screw’s solar products to meet the load requirements.

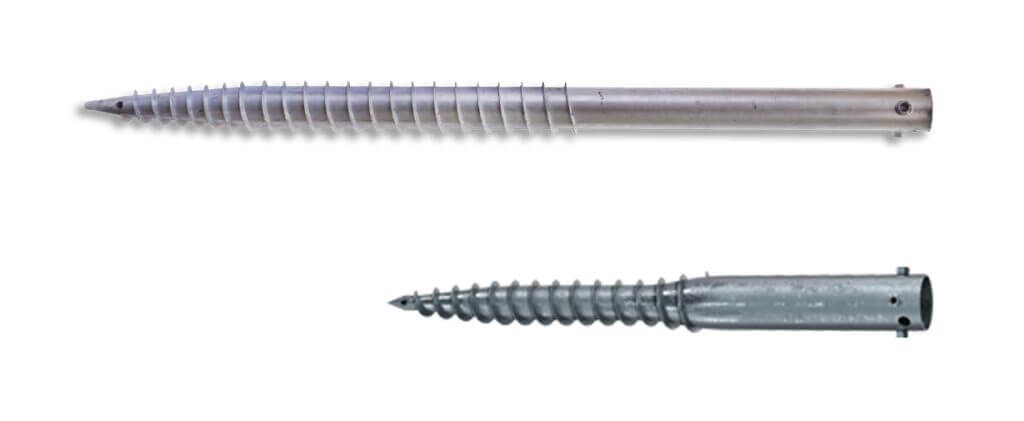

Ground Screws

Ground screws perform well in a wide variety of soil types and conditions, from sandy and rocky to hard-packed clay. IronRidge completed compatibility testing with Krinner Foundations Solar Ground Screws (G-Series) or American Ground Screws (Model 3) and now offers a certified systems engineering letter. Solar designers can acquire the letters on the Ground Mount Design Assistant platform.

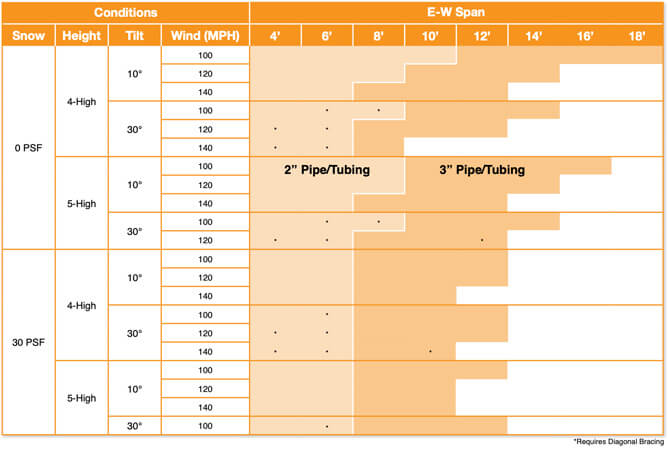

SPAN AND PIPE CHART

Refer to the following table to see how size impacts the East-West span between foundations. The table complies with ASCE 7-16 structural code. Values are based on 72-cell modules in Wind Exposure Category B.

Tech Specs

| Module Tilt Range: | 0 to 45 degrees |

| Module Orientation: | Landscape |

| E-W Pier Spacing: | Up to 17' |

| N-S Pier Spacing: | Up to 9' |

| Max Wind Speed: | 160 Mph |

| Wind Exposure: | Category B, C & D |

| Maximum Snow Load: | 60 psf |

| Materials: | Aluminum Cast Steel ASTM A216 A53 GR B (SCHED 40) Galvanized Mechanical Tubing Stainless Steel Fasteners |

| Warranty: | 25 Yr Mfg, 10 Yr Structural |

| Optional Bracing: | Yes |

| Adjusts to Elevation Change: | Yes |

| Integrated Grounding: | Yes |

| Wire Clips: | Yes |

| End Caps: | Yes |

| T-Bolts: | Yes |

| Engineering Support: | Yes (P.E. Certified) |

| Locally Sourced Pipe: | Yes. Must be Schedule 40 or Mechanical Tubing.

Mechanical tubing must meet following minimum requirements:

2” Mechanical Tubing:

3” Mechanical Tubing:

|

Ground-Based Design Assistant

- Comprehensive reaction forces

- Turbo-charged calculation engine

- Auto-generated documents package

Ground Mount Documentation

Ground Mount