IronRidge Ground Mount Now Integrated with Ground Screws

The IronRidge Ground Mount System can be designed and anchored with ground screws— also referred to as earth screws. These ground-based screws are gaining popularity as a foundation choice because of their versatility, installation speed and lower environmental impact.

We’re here to support you along the way and help you find what you need to get a permit for your ground-based solar project.

Designing & Building with Ground Screws

Using a ground screw foundation begins by creating a project in the IronRidge Ground-Based Design Assistant with your site conditions and soil class. If you do not know your soil class, you can either contact your local AHJ, check online to see if a soil survey report is available for your area, or hire a geotechnical engineer to assess the site. Certain sites may require a site-specific soil report or ground screw load testing.

Design Assistant will provide the span between piers, the quantity of ground screws and your complete bill of materials for the ground array. To make the ground screw selection process easier IronRidge has approved two ground screw manufacturers. Krinner Foundations and American Ground Screw make the only compatible ground screws engineered and included in the IronRidge Ground Mount certification letter and installation manual.

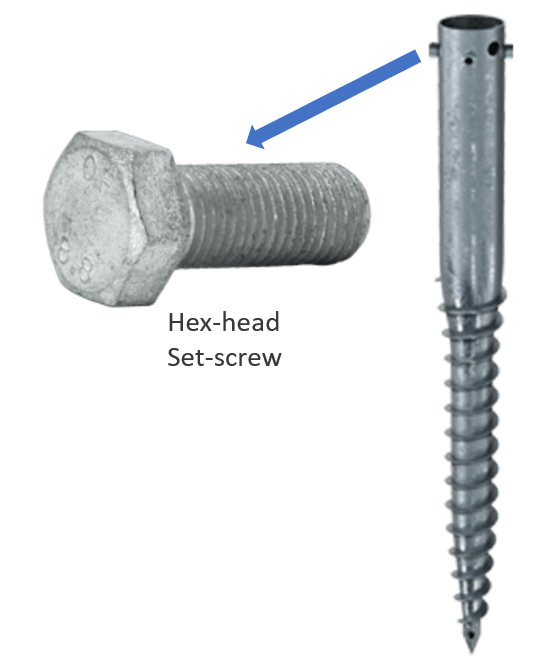

As part of the installation process, you will need the IronRidge Set Screw. This custom component is required to connect the IronRidge Ground Mount foundation pipe to the ground screw. American Ground Screw’s require 3 set screws per ground screw. Find quick resources for hex-head set screws here.

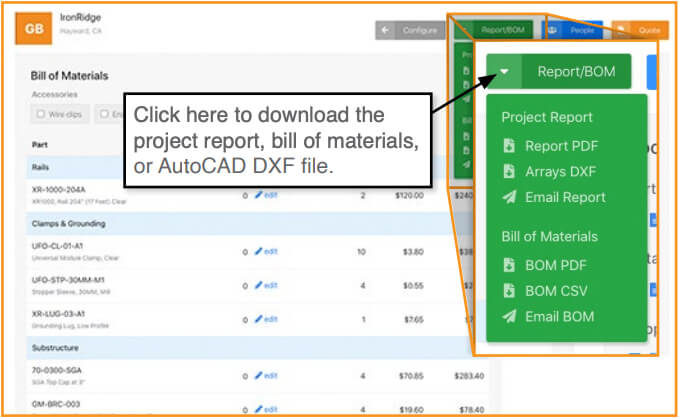

Obtaining Permitting Documents

Within Design Assistant, IronRidge will provide you with many of the permitting documents that an AHJ may require, including a project document with array drawings, state certification letters, CAD blocks, and cut sheets. Remember to check with your local AHJ on requirements, which will vary by region. Please note that the IronRidge Ground Mount Installation Manual also serves as the official ETL listing document and includes a complete list of compatible PV modules.

Ground Screw Installation

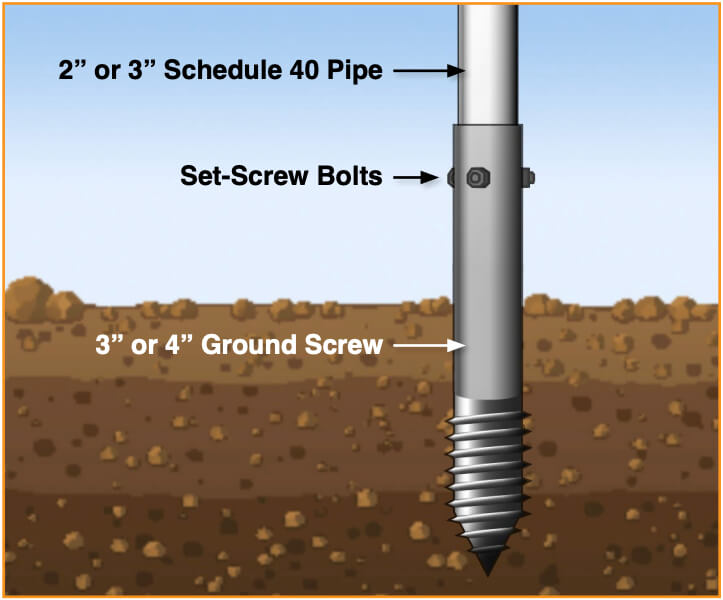

Always check with the ground screw manufacturer for installation instructions and use the IronRidge Ground Mount Installation Manual when assembling your array. Most manufacturers offer a screw which will allow for the insertion of the vertical tube into the ground screw. IronRidge recommends you select an earth screw without a flange.

To connect the IronRidge Ground Mount System to your ground screw, you simply insert the downtube pipe into the top of the installed screw and tighten three or four set-screw bolts to the appropriate torque.

The screw’s inside dimensions must be slightly larger than the pipe used in the system’s substructure. For example, a 76mm (3” OD) ground screw can be used with 2” schedule 40 pipe, while a 102mm (4” OD) screw can be used with 3” schedule 40 pipe. IronRidge Ground Mount can be built with either 2” or 3” schedule 40 pipe.

UL 2703 CERTIFICATION

All IronRidge Systems have been listed to UL 2703, the standard for evaluating solar mounting systems. This ensures they maintain strong electrical and mechanical connections over an extended period of time in extreme outdoor environments.

25-YEAR WARRANTY

IronRidge products come with a 25-year warranty, guaranteeing they will be free of defects in materials and manufacturing which materially impair the use of the products for the purposes for which they were designed.