IronRidge Ground Mounts provide a strong mounting structure for locations where roof access is not practical or available.

Up until recently, the only option we provided with our pre-engineered system was concrete foundations. Now, we have added an option for ground screw foundations to our online tool, Design Assistant, and certification letters with engineering seals in 44 states.

Ground screws allow for faster installation time with less impact on the environment, when compared to concrete foundations.

One of the most common questions regarding grounds screws is: “How are they installed and what type of equipment is required?”

Basically, it depends on the soil type at your location and the size of the ground screw. In lighter soils, with the smaller screw size, a handheld electric driver can be used.

In most cases, a machine-mounted, low-speed, and high-torque driver is best. These can be mounted on skid steers and mini excavators.

The best way to keep it straight is to use two levels with magnets attached to the ground screw, making adjustments as you go.

We are partnering with American Ground Screw. You can find equipment and installation videos on their websites and YouTube channels, like this one: American Ground Screw – Ground Screw Installation Instructional Video

They also rent equipment and have an installer network if you just want to contract with someone to install the screws.

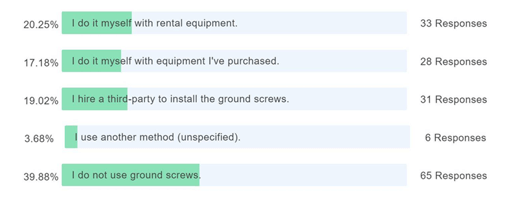

A recent survey shows a near three-way tie for how solar installers handle the installation of ground screws.

Contact us at support@ironridge.com for any additional questions.

Special thanks and credit to Jon Haeme, our Senior Technical Product Support Representative, for providing his expertise on this topic.