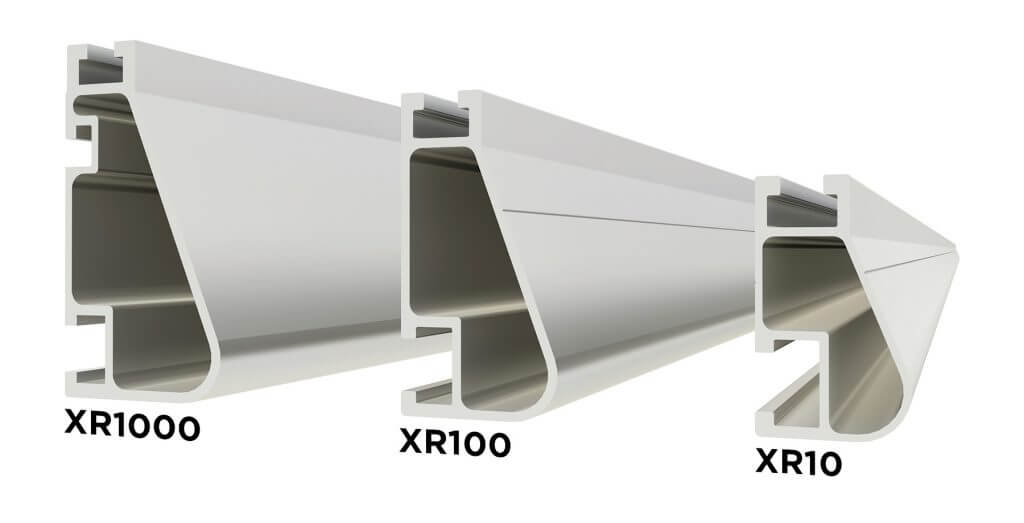

Strength runs in the family.

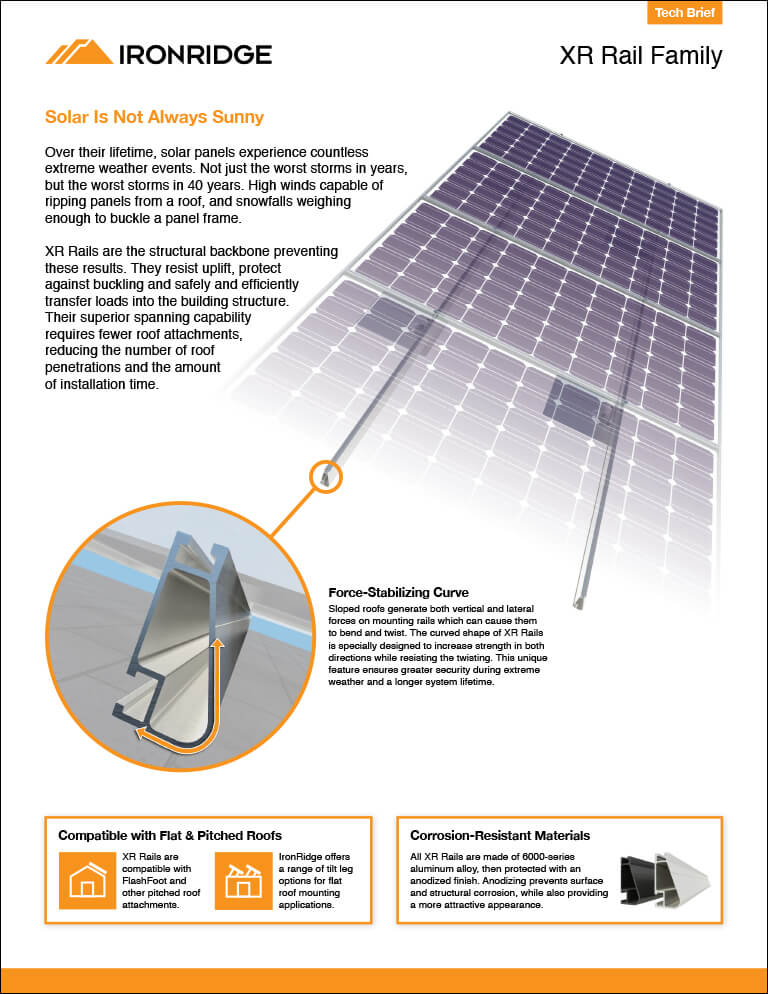

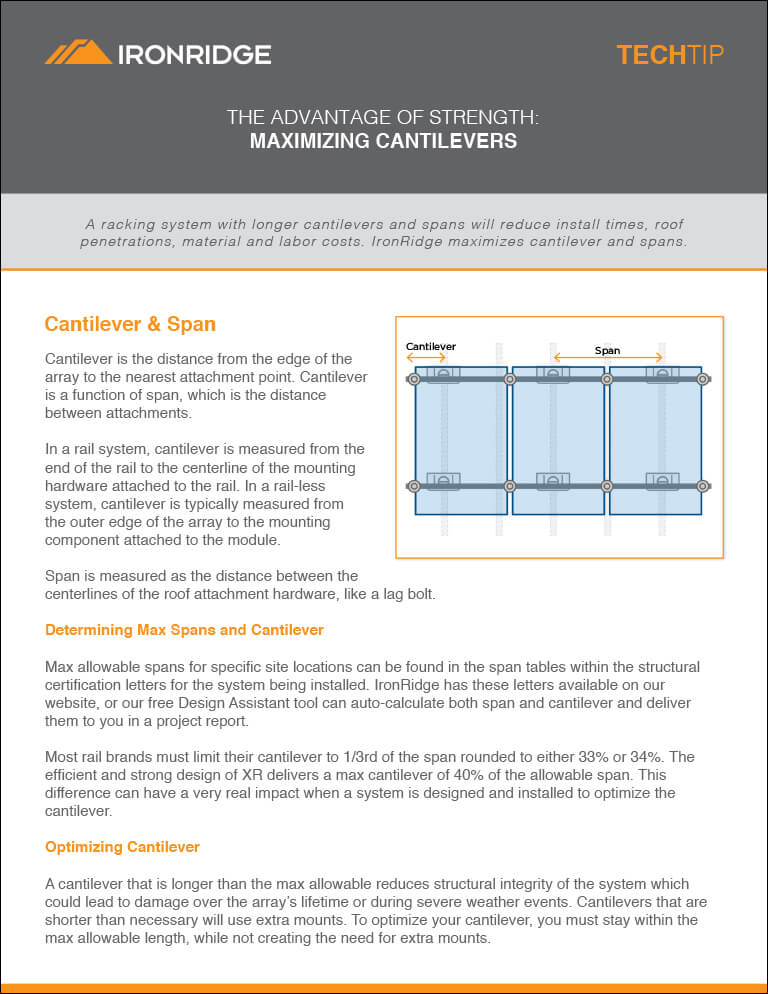

XR Rails® are the structural backbone of IronRidge® pitched, flat and ground-based arrays. Their signature curve helps them to resist uplift, protect against buckling and safely and efficiently transfer loads into the building structure.

Their superior spanning capability requires fewer roof attachments, reducing the number of roof penetrations and the amount of installation time. Each size supports specific design loads, while minimizing material costs. Depending on your location, there is an XR Rail® to match.

Force Stabilizing Curve

The curved shape of XR Rails® is specially designed to increase strength in both directions while resisting the twisting. This unique feature ensures greater security during extreme weather and a longer system lifetime.

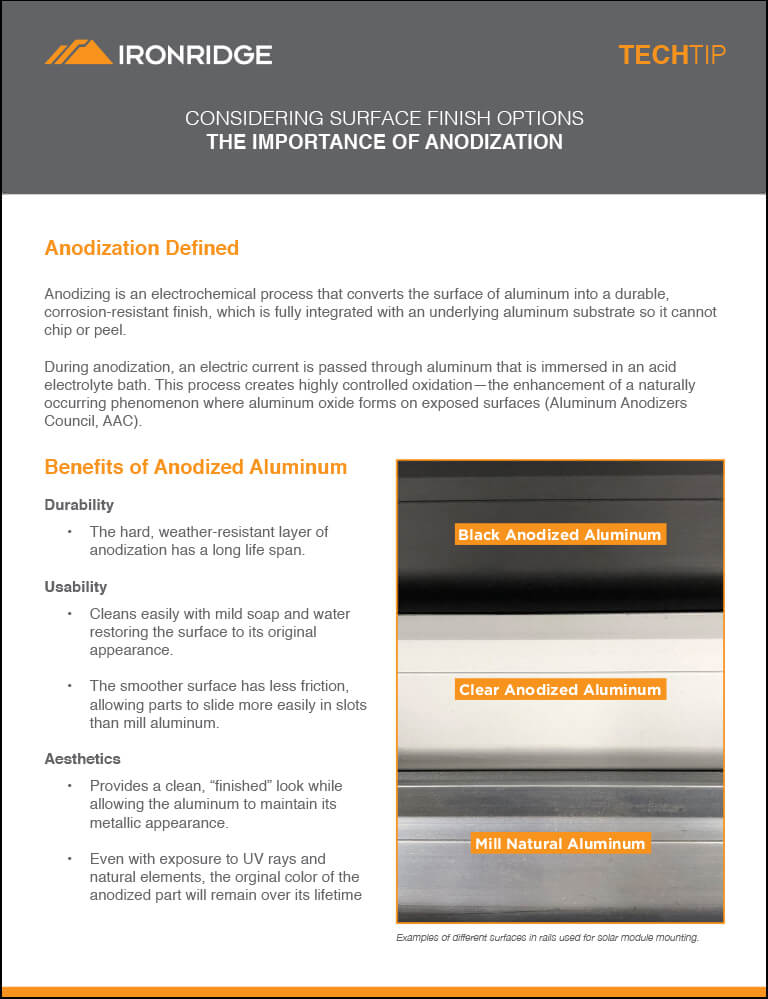

6000-Series Aluminum

All XR Rails® are made of 6000-series aluminum alloy, with anodized options offered as well—to prevent corrosion and provide a more attractive appearance. Available in mill and black-anodized finish.

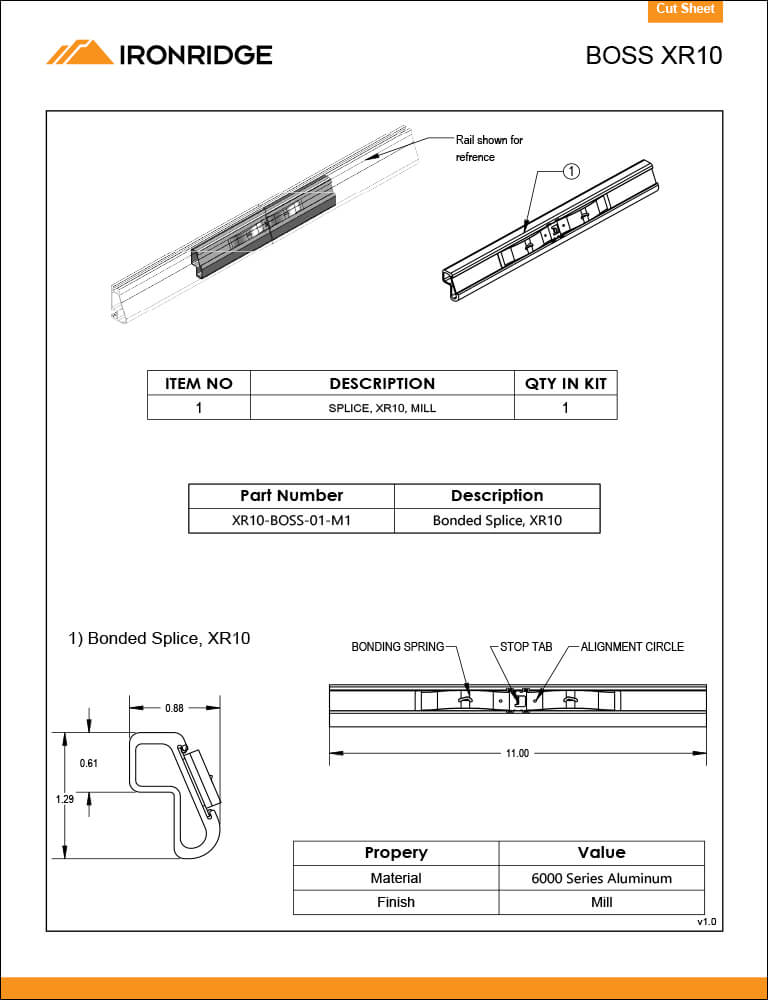

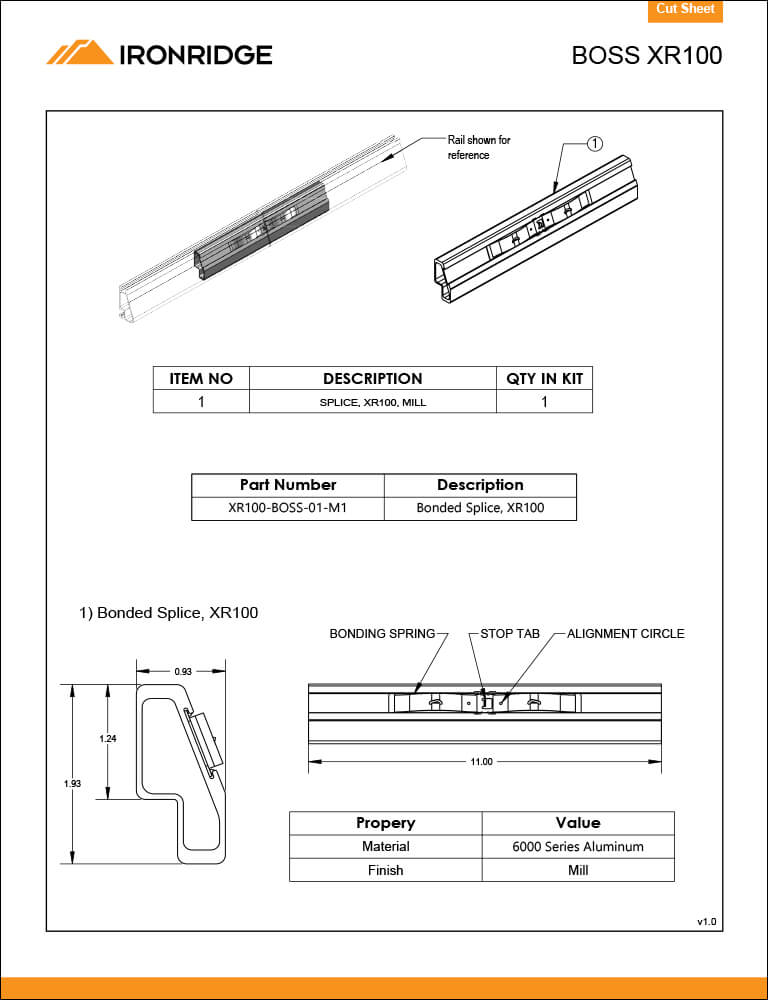

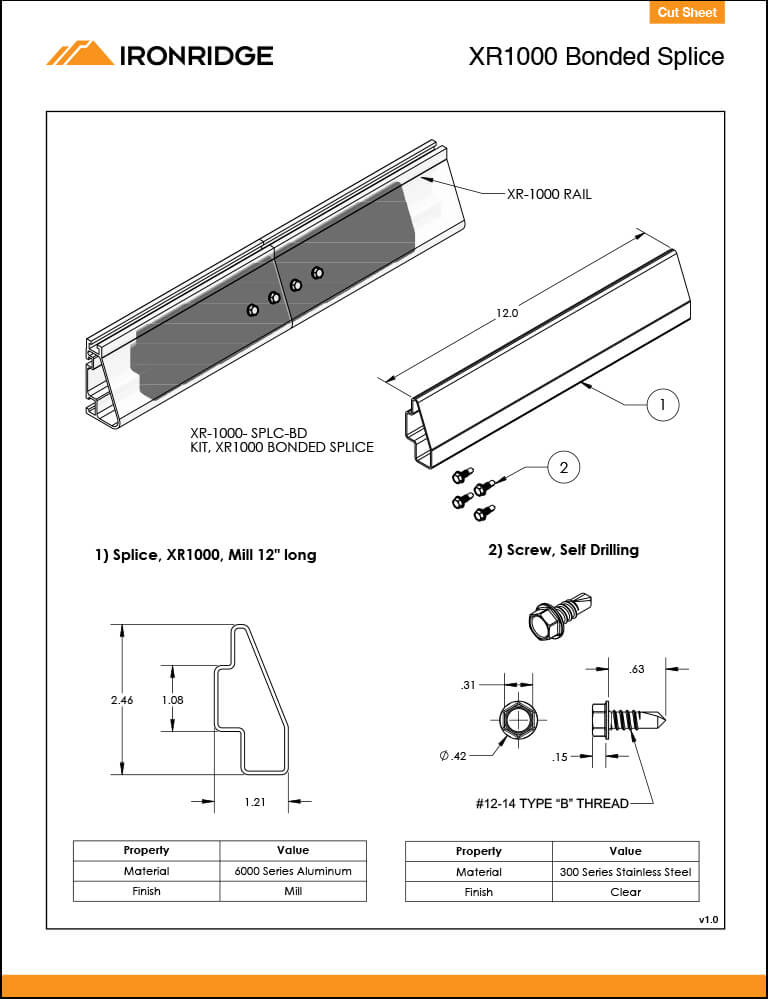

Bonded Structural Splices

The BOSS® (Bonded Structural Splice) provides a strong connection for linking multiple XR Rails®. No assembly, tools, or hardware required. The built-in bonding spring bites into rail, meeting all UL standards.

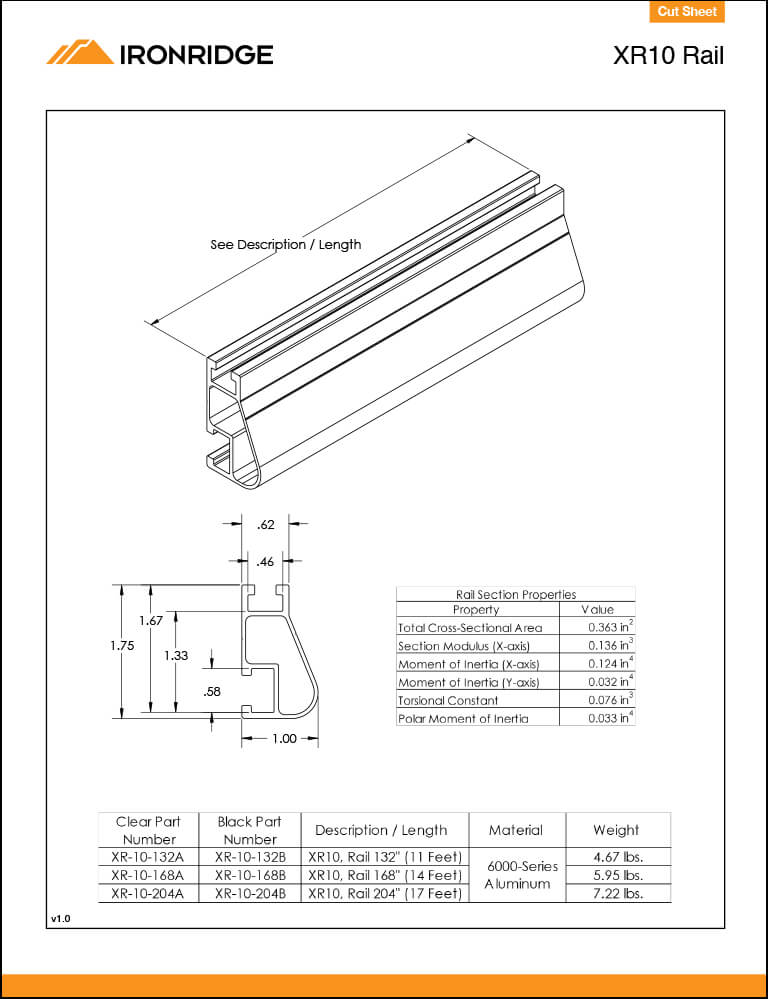

XR10® RAIL

XR10® is a sleek, low-profile mounting rail, designed for regions with light or no snow. It achieves 6 foot spans, while remaining light and economical.

- 6’ spanning capability

- Moderate load capability

- Mill & black-anodized finishes

- Internal splices available

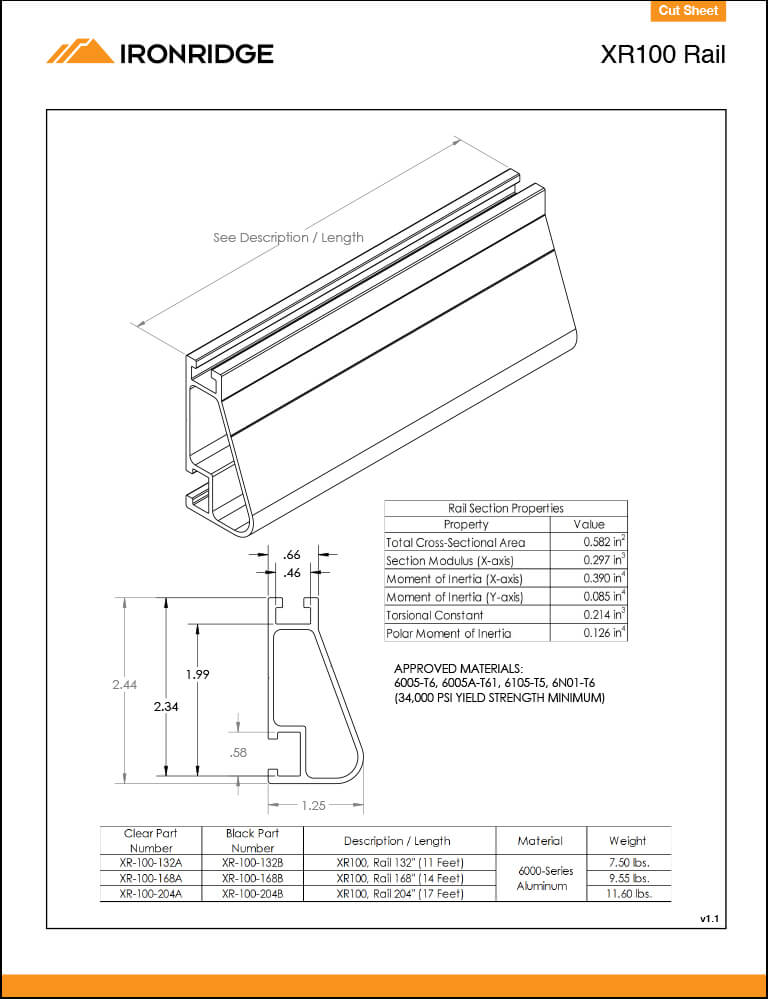

XR100® RAIL

XR100® is the ultimate residential mounting rail. It supports a range of wind and snow conditions, while also maximizing spans up to 8 feet.

- 8’ spanning capability

- Heavy load capability

- Mill & black-anodized finishes

- Internal splices available

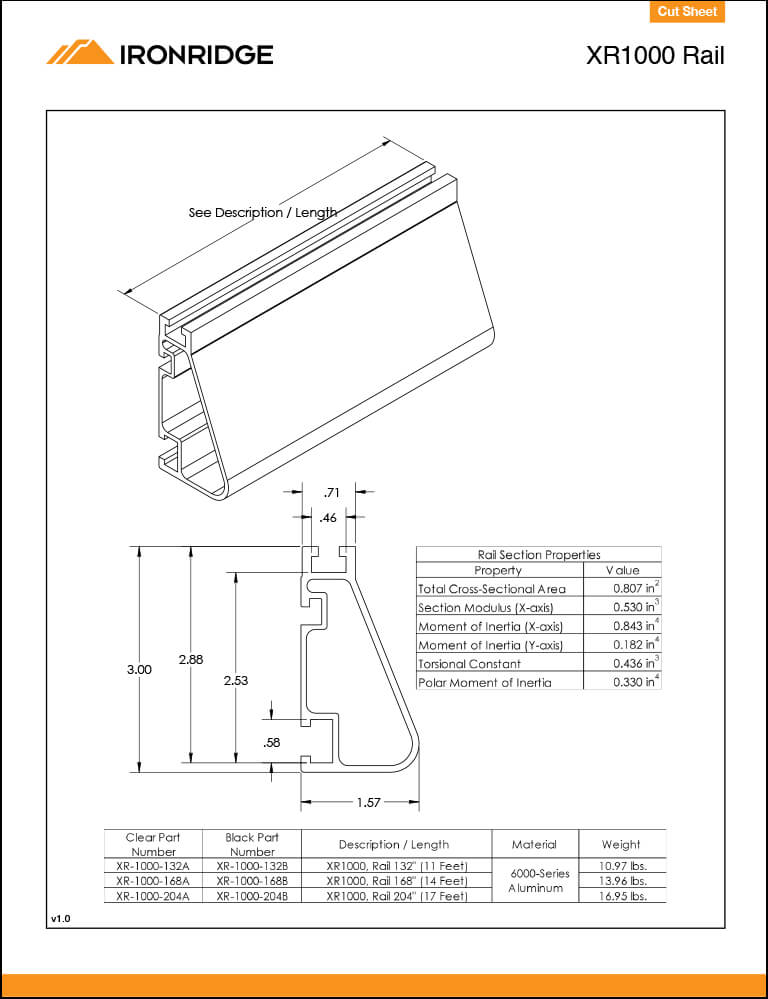

XR1000® RAIL

XR1000® is a heavyweight among solar mounting rails. It’s built to handle extreme climates and spans up to 12 feet for commercial applications.

- 12’ spanning capability

- Extreme load capability

- Mill, non-anodized finish

- Internal splices available

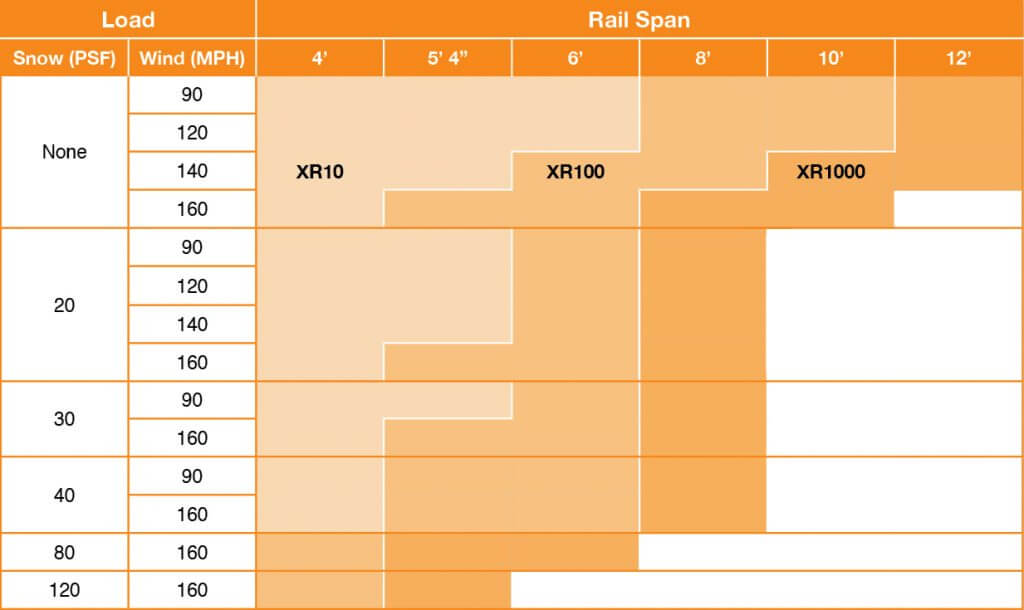

XR Rail® Selection

The adjacent table provides a quick guide on how each rail supports regional circumstances.

Values are based on the following criteria: ASCE 7-16, Gable Roof Flush Mount, Roof Zones 1 & 2e, Exposure B, Roof Slope of 8 to 20 degrees and Mean Building Height of 30 ft.

For ASCE 7-10 spans, click here.

Refer to the detailed span tables and certification letters on our resources pages for more precise design specifications.

XR RAIL® DOCUMENTATION

UL2703 Certification

All IronRidge® Systems have been listed to UL 2703, the standard for evaluating solar mounting systems. This ensures they maintain strong electrical and mechanical connections over an extended period of time in extreme outdoor environments.

25-Year Warranty

IronRidge® products come with a 25-year warranty, guaranteeing they will be free of defects in materials and manufacturing which materially impair the use of the products for the purposes for which they were designed.