All Your Solar Project Needs in One Place

Our Design Assistant tools will guide you through each project phase — including design, quoting, permitting, and installation.

Making a free account unlocks additional functionality:

- Save and edit projects

- Share designs with others

- Send orders to distributors

Questions? Call us at 1-800-227-9523.

Applications for Every Project Type

What’s New in Design Assistant?

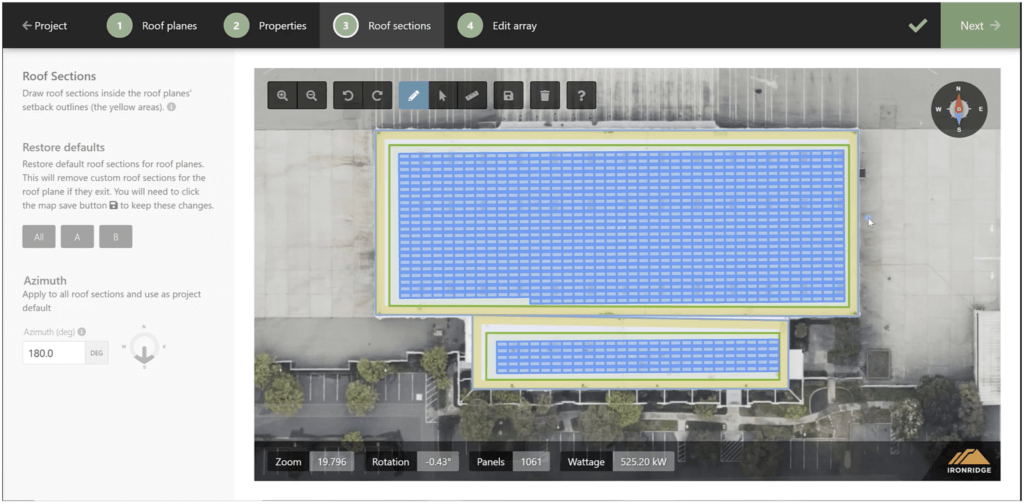

Visual Editor for BX Systems

A sophisticated visual editor is now available in the BX Design Assistant—great for small commercial projects with complex roof shapes, panels skewed to roof edges, and multiple roof planes.

GreenLancer Permit Packs

Now installers can purchase solar permit plans, structural and electrical plans right from Design Assistant with a click of the button. Simply select the “Permit Pack” option at the top of the Bill of Materials page on your next Pitched Roof or Ground-Based Design Assistant project to request plans from GreenLancer.

You can trust GreenLancer’s nationwide network of solar design and engineering firms for their guidance and support in delivering proposals, permit-ready drawings, and Professional Engineering reviews. Thanks to this partnership, you can take advantage of deep discounts as well (~25% off most offerings).

Learn more at IronRidge.com/GreenLancer.